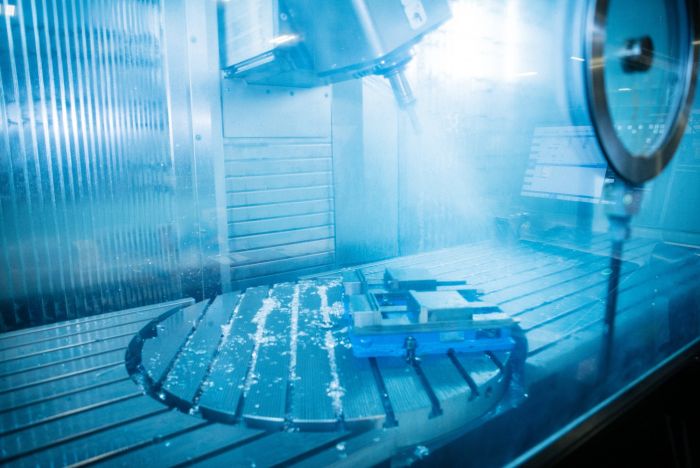

CNC Machining

Our highly skilled CNC machinists have over 150 years of combined experience. This plus the latest technologies in equipment, tools and software reduces our setup and cycle times so that we can deliver high quality, precision-machined parts at a reasonable cost and lead time.

Manual Machining

With over 125 years of combined experience, our highly skilled machinists are capable of handling projects of almost any size and shape using 40+ different machines to get the job done according to your specifications.

Building Exterior